Lean Six Sigma improves the quality and consistency of an organization. You’ve come to the right place if you’re eager to learn what is lean six Sigma? This article will teach how you can use Lean Six Sigma to drive up your profit with the most customer satisfaction. Furthermore, you will learn about the principles of streamlining a business operation.

We’ll walk you through the Lean Six Sigma principles, definition, importance and processes. If you have no prior experience in this field, you will learn what lean six Sigma is. You will get a sense of what it entails. What kind of job prospect will you have access to by gaining knowledge and expertise? And how to properly execute lean and six sigma principles? So, let’s get started!

Table of Contents

What is Lean Six Sigma?

Six Sigma is a methodology that gives businesses the resources they need to develop their business process. This change in efficiency and reduction in process variance helps to reduce defects. Besides, it boosts earning, employee productivity, and product or service quality.

Lean Six Sigma is a tool for reducing waste and increasing consumer satisfaction. For efficient problem-solving, this managerial concept employs the Lean and Six Sigma approach. When a team uses this method, they can avoid problems with a service or product. Besides, lean six sigma principles remove potential financial waste.

Difference between Lean, Six Sigma & Lean Six Sigma

Now that we know what lean six sigma is, let’s discuss the differences between Lean & Six Sigma.

Six Sigma is concerned with reducing process variation and improving process control. In contrast, lean is concerned with eliminating waste (non-value-added processes and procedures). Furthermore, lean promotes work standardization and flow.

Since process improvement involves elements of both methods to achieve meaningful results, the distinction between Six Sigma and lean have blurred. Hence, many organisations are using the word “lean Six Sigma” more frequently. When it comes to identifying problems, Lean focuses on waste (Muda, mura, muri). In contrast, Six Sigma focuses on variation or any deviation from the target results.

Lean Six Sigma is a data-driven, fact-based improvement theory. It:

- Prioritizes defect prevention over defect detection.

- Improves customer loyalty and bottom-line performance.

- Lowers variance, waste, and cycle time.

The process encourages job standardization and flows, resulting in a competitive advantage. Therefore, it applies everywhere there is waste, and every employee should be a part of it.

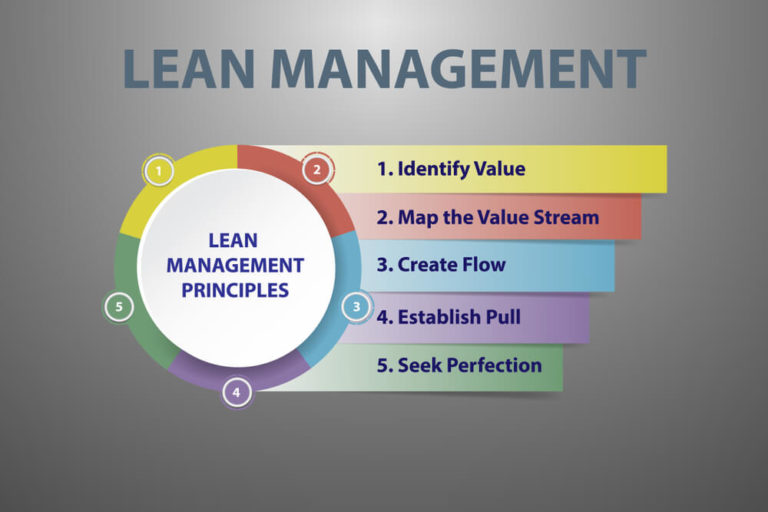

Lean Six Sigma is a collaborative management approach. It solves problems using a collective lean toolkit. The company goes through five principles of Lean Sigma to reduce waste and fix issues. Following the principles of lean six Sigma is a must for maximum efficiency.

What are the Lean Principles?

Lean manufacturing has long been thought to be a way to increase manufacturing productivity. But it can be extended to any sector or production process in any industry. Lean, for example, industries such as manufacturing, finance, healthcare, IT, and the military are using lean principles.

On a smaller scale, the concepts can even be used to organise your laboratory or workspace.

Toyota first developed lean as part of the Toyota production system. It was built around the work of Shewhart & Deming. Toyota was a client of Deming’s. Since then, the company based its operational management activities on his teachings. The removal of waste is the central tenet of Lean.

In reality, “a collection of tools that assist in the detection and continuous removal of waste” is a reasonable definition of the Lean approach. If a company, such as Toyota, engages in large-scale, high quantity manufacturing, a waste-involved method indicates that the company generates large-scale, high-quantity waste. This is something that no organization wants to do. Also, the Lean methodology analyses the company process with software.

In manufacturing, there are five fundamental lean principles.

Value

The needs of the customer often determine the value of a commodity. What is, for example, the production and distribution schedule? What is the starting point for the price? Furthermore, what are the other critical conditions or demands that must be fulfilled? This data is critical for determining meaning.

Map the Value Stream

After determining the value (end goal), the next step is to chart the “value stream”. It involves all the steps and processes involved in bringing a given product from raw materials to delivery to the consumer. Thus, value-stream mapping is a straightforward exercise. It describes all the activities that move a product or service through a process.

Design, administration, manufacturing, procurement, HR, distribution, and customer support are all examples of processes. The aim is to create a “map” of the material/product flow through the process on one page. Furthermore, to recognize any move that does not add value, make plans to get rid of them. Process re-engineering is another term for value stream mapping. You will have a greater understanding of the entire company process with this.

Flow

After removing waste, the whole department must become cross-functional. It makes sure the remaining steps in the manufacturing process remain free of delays. Altogether, this will lead to huge gains in creativity and efficiency.

Establish Pull

With improved flow, the time for marketing a product and delivering it to the customer is shortened down. Your customer can buy a product from you and get it delivered instantaneously in weeks. They don’t have to wait for months. Meanwhile, your company gets to cut back on the huge expenses of inventory. Because there is no need to stockpile resources or build the product in advance.

Thus, this step lets you cut back on production cost, making the price of the goods cheaper. In addition, this phase makes your customer more satisfied.

Seek Perfection

Getting through Steps 1-4 is a good start. However, the fifth stage is probably the most crucial. It helps incorporate lean thinking and process management into the company’s culture. As the gains continue to mount, keep in mind that lean is a dynamic framework. Hence, it needs relentless effort and diligence to perfect.

Every employee should be a part of the lean implementation process. Experts say a method needs to pass through value stream mapping multiples times. Then it will be considered an authentic lean process.

Six Sigma Principles

Motorola was the first to produce Six Sigma in the late 1980s. Bill Smith, a quality engineer, developed the technique. He wanted to cut out mistakes. His intention was to improve the operation process of quality and measurement. The Motorola systems were tolerant of error rates. And it resulted in excessive scrap, rework and redundant testing. Besides, it caused huge customer frustration.

The Six Sigma methodology aimed to recognize and eliminate any source of variation in the process. Because the lack of variation will give a predictable result. However, this result can be accepted only if it is error-free and meets customer satisfaction.

The four stages of Six Sigma are:

Define

This phase sets the boundary for the process under investigation. The probable outcome is set according to customer expectation or feedback. In short, this phase primarily focuses on enhancing customer experience.

Analyse

The current output of the process, product, or service is evaluated in this step. It determines what is actually happening, particularly from the perspective of the customer. This phase ensures that the study and solution are based on real-world performance. In essence, it doesn’t rely on hypothetical or anecdotal data.

Improve

This step evaluates potential improvements to the method, product, or service. The team then moves on to design and test a collection of changes and solutions. In addition, it ensures that the solution has the desired effect. The variance is minimized or removed in this phase.

Control

This phase introduces the modifications and changes the supporting systems. Furthermore, the project team places the process, product, or service under review. The team uses statistical process control. This phase also ensures the complete execution of the solution. The control measures detect if output begins to deteriorate.

Different Six Sigma Qualifications

SIX SIGMA offers a variety of certifications, also known as “belts.” Yellow, Green, Black, and Master Black are the most widely used and recognized Six Sigma Belts. Certain organizations often assign white Belts. Six Sigma has no uniform certification body. The Belts do not build on each other or serve as prerequisites.

The following is a brief rundown of the various Six Sigma Belts:

Six Sigma White Belt

It is the entry-level qualification that covers the fundamentals of Six Sigma. White belts aid programs by assisting in change management in the company. Also, they work with local problem-solving teams.

Six Sigma Yellow Belt

The Six Sigma Yellow Belt Certification is for those who are new to the Six Sigma universe. It covers the basics of using Six Sigma tools and methodologies within an organization and the benefits of doing so.

Six Sigma Green Belt

Learners with the Six Sigma Green Belt degree will be able to work under the guidance of a Six Sigma Black Belt. Job responsibilities include gathering data, conducting research, and resolving quality issues. If you are qualified, you will be able to apply what you’ve learned to boost the efficiency of your own smaller-scale projects.

To begin studying, a Green Belt must have at least three years of work experience. Occasionally, the requirement for experience and skill might be relaxed depending upon the acquired skill set.

Six Sigma Black Belt

Individuals with a Six Sigma Black Belt certification are experts in their field who can thoroughly clarify Six Sigma philosophies and values. Having a six sigma black belt will make you capable of delegating and become a team leader. Also, you will have a detailed understanding of all aspects of the DMAIC model. In addition, you will have a basic understanding of Lean in compliance with Six Sigma principles.

To get started as a Black Belt, you must have three or more years of experience in one of the areas covered by the Six Sigma body of information.

Master Black Belt

Individuals who achieve the rank of Master Black Belt in Six Sigma are able to teach others the concepts of Six Sigma. You’ll learn how to create key metrics and a strategic direction, which will eventually inform all of a company’s Six Sigma decisions.

Lean Six Sigma Principles

Both Lean & Six Sigma define value based upon the customer’s experience. Lean & Six Sigma principles are most compatible when implemented together. Data collection in Lean Six Sigma Project can support both lean analysis & six sigma analysis. In short, improvements using either approach will reduce waste and variation.

Lean Six Sigma is not only used in manufacturing operations. The principles are integrated and used in all industries. For instance, government, consumer, education and non-profit organizations.

Successful programs throughout industries adopt the following lean six sigma principles:

Addressing a Real-World Problem

Lean Six Sigma is a bottom-up and top-down approach. Problem selection is linked to the top-down aspect. The Lean Six Sigma project teams are concentrating on real-world issues that are currently affecting consumers and processes.

When it comes to rework and repair activities, as well as dealing with customer concerns, team members are often affected by the issue. This gives the project a sense of urgency and relevance. It isn’t just “busy work,” but genuine work.

Team Analysis

A cross-functional team usually handles the Lean Six Sigma projects in a company. A cross-functional analysis is needed to prevent the sub-optimization of the process. Consequently, the viewpoints of the organizations involved and affected by the project are included in the problem analysis by including a cross-functional team.

A cross-functional team plays a key role in the implementation of the solution. The different team members’ in-depth experience is beneficial in understanding the issue and the consequences of the data. These diverse viewpoints are critical in assisting the team in developing a solution. Overall, team analysis solves the immediate issue while also reducing waste and variation in other areas of the process.

Solution Addresses Problem’s Root/Cause

The methods used in Lean Six Sigma are used to determine if the problem is caused by a particular cause or a general cause. Your project team will be able to find the real root cause or causes after making this distinction. In addition, the team should devise a problem-solving approach that is suitable for the situation. If the trigger is unique, you may devise a unique solution. The team should redesign the mechanism if it is a common cause.

Control Phase

The final step of lean six Sigma is the control phase. In the control phase, the organization updates the corresponding system and implements the solution. In addition, the project team coaches process operators and managers on the use of the solution.

Why Should You Become Lean Six Sigma Qualified?

Six Sigma certifications will reflect your dedication to enhancing quality and efficiency. Also, it will demonstrate your logical thinking abilities. Practitioners of the technique are still in demand because they are well-respected in a variety of industries.

Whatever your job, being Lean Six Sigma certified will help you stand out by improving your leadership skills. It will demonstrate to potential employers that you can reduce costs, increase sales, and, eventually, improve their business processes. When you add in better work prospects and higher wages, it’s easy to see why so many of the world’s largest businesses consider Six Sigma an essential part of their organization.

Benefits of Becoming Lean Six Sigma Certified

Adding six sigma certification to your CV demonstrates your commitment to expanding your business knowledge. The certification also dictates your strong analytical skills.

Few reasons why you should become certified are:

Business & Quality Development

You’ll be able to assess a company’s production and business processes. Becoming a lean six sigma certified, you can make recommendations for improvement. Furthermore, you’ll be able to do a thorough examination of existing policies and determine the efficiency.

Rise to Managerial Position

Professionals with a Six Sigma degree will improve their risk evaluation and financial management skills. For senior management positions, such skills are highly respected by middle and top-level management. Once you are certified, you’ll have a clear understanding of executing any lean six sigma team project.

Gain Credibility

Your company will have faith and confidence in you because of your relevant qualifications. Your credentials will instil trust in your clients about your credibility and ability to perform. Being a certified six sigma trainer proves that you will ensure the quality of your managed projects.

Job Prospects of Lean Six Sigma

To introduce Lean Six Sigma in an organization, you can work as a contractor or a permanent employee for companies of all sizes. The criteria and performance requirements of the company decide the work titles you employ.

Some work positions are:

- Six Sigma Analyst

- Six Sigma Consultant

- Six Sigma Project Manager

- Lead Analyst

- Functional Product Lead

- Senior Project Manager

- Business Process Manager

- Director of Operational Excellence

If you are working in manufacturing as a Lean Six Sigma professional, you may have to fulfil the duties of the following:

- Operating system specialist

- Project engineer

- Reliability engineer

- Lead manufacturing engineer

- Compliance structural engineer

In the healthcare industry, you will be responsible for:

- Preventing medical errors

- Reducing medical supply waste

- Improving patient care

- Shortening the length of patient’s staying duration

- Reducing mortality rates

Salary Guidelines

Your salary will depend on the type of company and your position. In addition, your certifications will act as a huge determiner. Once qualified, you could earn £42,000 per year on average. Some companies offer targeted bonuses along with additional benefits. With enough experience, you could move up the ladder and take up managerial roles at the company. An experienced practitioner can earn £60,000 on average per year.

Importance of Lean Six Sigma

The current world is extremely complex. In this complex setting, a lean or six Sigma approach implemented in isolation will not yield the maximum potential for change. The combination of Lean and Six Sigma guarantees excellent results. Traditionally, the lean technique is used first to eliminate waste in a process in this management strategy. Six Sigma instruments are then used to optimize process variances.

Every sector and market uses the integrated Lean Six Sigma management approach. It encourages dramatic improvements in an organization’s efficiency. In different industries around the world, Lean Six Sigma leads to competitive advantages. They may be a product or service-based businesses. The Lean Six Sigma approach strengthens and streamlines operations. Management support, employee engagement, and a dedication to improving customer loyalty are the keys to success.

Related:

1. How to Set SMART Goals to advance your Career

2. 7 Ways To Boost Your Career Prospects While Still At University

Conclusion

The significance of Lean & Six Sigma principles cannot be overstated. You must stay competitive and employable in a world where work opportunities are shrinking. Learning the process and integration of lean six Sigma can present many job opportunities. As an employer, you can rest easy knowing that your production lines are being managed by experts whose primary concern is quality.

Recent posts

- When Should You Start Writing Your College Essay? A Strategic Timeline for Success

- 12 Easy Ways to Learn Even and Odd Numbers

- Top 5 Study Tools for College Students

- 11 Essential Tools Every Online Learner Needs in 2024

- How to Leverage the Global Talent Visa for Advancing Your Education

- From Study Notes to Assignments: 15 Ways PDF Editors Boost Academic Productivity

- How Blockchain is Transforming Education | 2024 Insights

- 5 Tips for Starting Your Cyber Security Analyst Career

- The Evolution of Online Assignment Help Services in the UK: Trends and Benefits

- Effective Time Management Strategies for Managing Online College Coursework

June 09, 2021

June 09, 2021